The Byford Dolphin accident is one of the most harrowing events in the history of offshore oil and gas operations. It serves as a grim reminder of the dangers faced by workers in extreme environments. The incident, which occurred on November 5, 1983, shocked the world and led to significant changes in safety protocols for diving operations. This article delves deep into the details of the accident, its causes, and the lessons learned that continue to shape the industry today.

On that fateful day, a catastrophic decompression event occurred aboard the Byford Dolphin, a semi-submersible drilling rig located in the North Sea. The accident claimed the lives of five divers and one dive tender, leaving an indelible mark on the diving community and the offshore oil industry. The tragedy highlighted the critical importance of stringent safety measures and the potential consequences of lapses in protocol.

This article will explore the background of the Byford Dolphin, the events leading up to the accident, and the subsequent investigations. We will also examine the profound impact the tragedy had on diving safety standards and how it continues to influence practices in high-risk industries. By understanding the full scope of this incident, we can appreciate the advancements made in safety and the ongoing need for vigilance in hazardous environments.

Read also:Bryan Johnsons Wife A Comprehensive Look Into The Life Of The Man Behind The Success

Table of Contents

- Background of the Byford Dolphin

- The Accident

- Causes and Investigation

- Impact on Diving Safety

- Lessons Learned

- Industry Response

- Safety Protocols Today

- Memorial and Legacy

- Conclusion

Background of the Byford Dolphin

The Byford Dolphin was a semi-submersible drilling rig operated by Dolphin Drilling, a company known for its expertise in offshore oil exploration. Commissioned in the late 1970s, the rig was deployed in the North Sea, a region renowned for its challenging weather conditions and rich oil reserves. The rig's primary function was to drill exploratory wells, requiring the use of saturation diving teams to perform underwater maintenance and inspections.

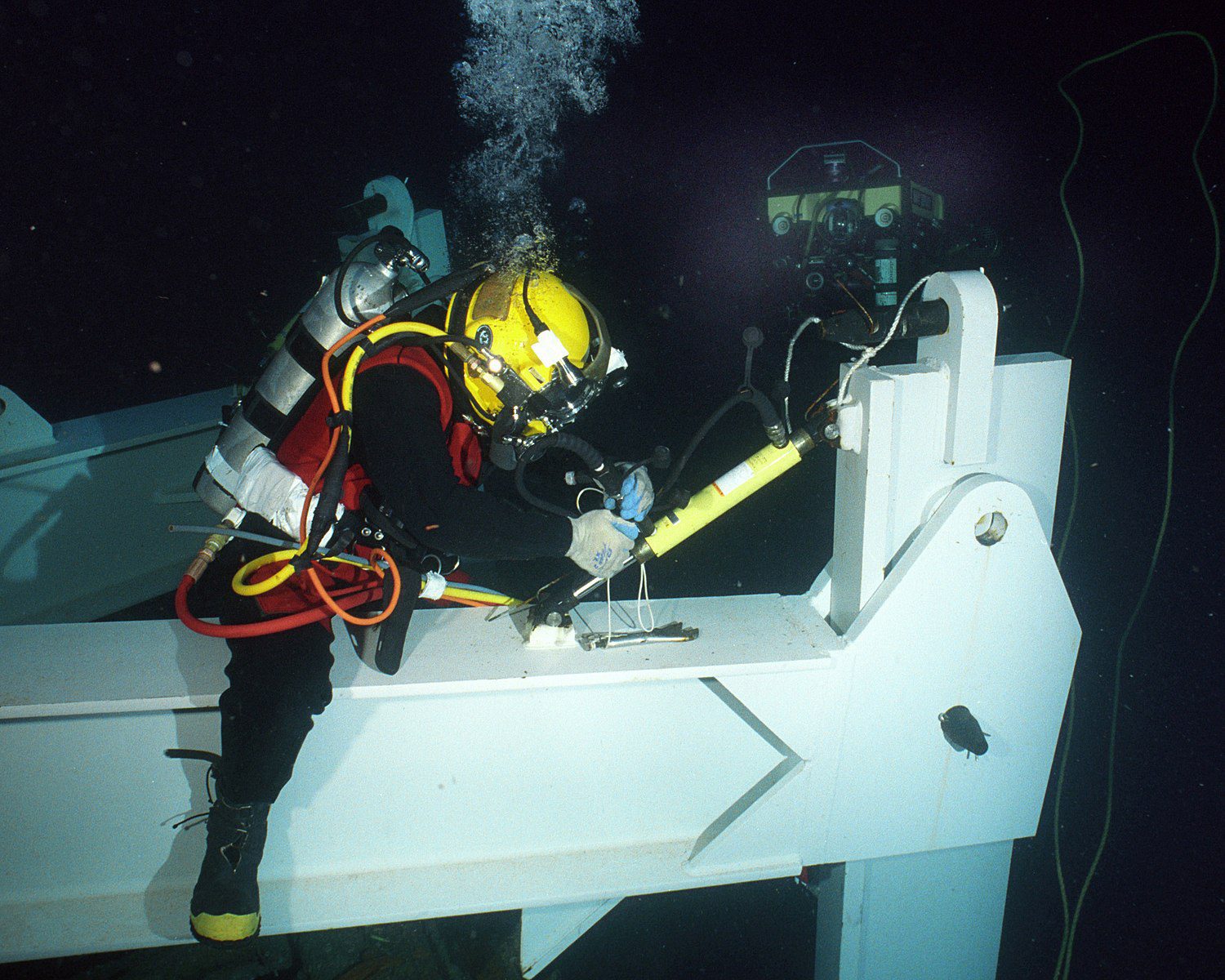

Saturation diving, a technique used to allow divers to work at great depths for extended periods, was a critical component of offshore operations. Divers would live in pressurized chambers aboard the rig, enabling them to acclimate to the high-pressure environment of the deep sea. This method allowed for more efficient and prolonged underwater work, but it also introduced significant risks, as the Byford Dolphin accident would tragically demonstrate.

Technical Specifications

- Type: Semi-submersible drilling rig

- Operator: Dolphin Drilling

- Location: North Sea

- Commissioned: Late 1970s

The Accident

On November 5, 1983, the Byford Dolphin was conducting routine operations in the North Sea. A team of saturation divers was preparing to return to the surface after completing their underwater tasks. The process involved transferring the divers from the diving bell to the deck decompression chamber, a procedure known as "bell-to-surface transfer."

As the divers were being transferred, a catastrophic failure occurred. The chamber's hatch opened prematurely, causing an explosive decompression. The sudden drop in pressure resulted in the deaths of five divers and one dive tender. The force of the decompression was so severe that it caused devastating injuries, with some victims suffering from explosive decompression injuries.

Victims of the Accident

- Trond A. Dokken - Dive Tender

- Bjørn Arne Bergersen - Diver

- Harald Espedal - Diver

- Kåre Håkenstad - Diver

- Oddbjørn Håkonsen - Diver

- Roy Sætrevik - Diver

Causes and Investigation

The immediate aftermath of the accident prompted a thorough investigation by Norwegian authorities. The inquiry sought to determine the cause of the catastrophic decompression and identify any lapses in safety protocols. Investigators discovered that the accident was caused by a combination of technical failures and human error.

One of the primary causes was the malfunction of the chamber's locking mechanism. The hatch was designed to open only when the pressure inside and outside the chamber was equalized. However, due to a failure in the pressure monitoring system, the hatch opened prematurely, leading to the explosive decompression. Additionally, it was found that the divers were not adequately briefed on emergency procedures, exacerbating the situation.

Read also:James Garner A Timeless Icon Of Hollywood And Television

Key Findings

- Failure of the chamber's locking mechanism

- Malfunction in the pressure monitoring system

- Inadequate emergency preparedness

- Communication breakdown between the dive team and surface crew

Impact on Diving Safety

The Byford Dolphin accident had a profound impact on the diving industry, prompting widespread reforms in safety protocols and equipment standards. Regulatory bodies and industry leaders recognized the need for stricter safety measures to prevent similar tragedies in the future.

One of the most significant changes was the implementation of enhanced training programs for divers and support personnel. These programs focused on emergency response, equipment maintenance, and communication protocols. Additionally, new regulations were introduced to ensure that all diving equipment met rigorous safety standards.

Safety Reforms

- Mandatory emergency response training

- Regular equipment inspections and maintenance

- Improved communication systems

- Standardized safety procedures

Lessons Learned

The Byford Dolphin accident served as a stark reminder of the inherent risks in offshore diving operations. It underscored the importance of meticulous planning, rigorous safety protocols, and continuous improvement in equipment design. The tragedy highlighted several key lessons that continue to guide the industry today.

First and foremost, the accident emphasized the critical role of equipment reliability. The failure of the chamber's locking mechanism was a direct result of inadequate maintenance and inspection. This led to the adoption of more stringent testing and certification processes for diving equipment. Additionally, the importance of clear communication and coordination between the dive team and surface crew became evident, prompting the development of advanced communication systems.

Key Lessons

- Prioritize equipment reliability and maintenance

- Enhance communication and coordination

- Implement comprehensive training programs

- Adopt a proactive approach to safety

Industry Response

In the wake of the Byford Dolphin accident, the offshore oil and gas industry took decisive action to address the safety concerns raised by the tragedy. Industry leaders, regulatory bodies, and diving organizations collaborated to implement sweeping reforms aimed at preventing similar incidents.

One of the most notable responses was the establishment of the International Marine Contractors Association (IMCA), a body dedicated to promoting safety and best practices in the marine contracting industry. The IMCA developed a comprehensive set of guidelines and standards for diving operations, which have since become the benchmark for the industry.

Industry Initiatives

- Formation of the IMCA

- Development of safety guidelines and standards

- Collaboration between industry stakeholders

- Regular safety audits and inspections

Safety Protocols Today

Today, the legacy of the Byford Dolphin accident is evident in the robust safety protocols that govern offshore diving operations. The industry has made significant strides in enhancing safety measures, driven by the lessons learned from the tragedy.

Modern diving operations are characterized by advanced technology, rigorous training, and stringent safety standards. Diving equipment is subject to regular inspections and maintenance, ensuring its reliability and performance. Additionally, divers undergo extensive training programs that emphasize safety, emergency response, and communication.

Current Safety Measures

- Advanced diving equipment

- Comprehensive training programs

- Regular safety audits

- Stringent regulatory standards

Memorial and Legacy

The Byford Dolphin accident left an indelible mark on the diving community and the offshore oil industry. In honor of the victims, memorials have been erected to commemorate their sacrifice and ensure that their memory lives on. These memorials serve as a poignant reminder of the importance of safety and the need for continuous improvement in hazardous environments.

The legacy of the Byford Dolphin accident extends beyond memorials. It has become a cornerstone of safety culture in the industry, influencing generations of divers and industry professionals. The tragedy continues to inspire advancements in safety technology and practices, ensuring that the lessons learned are never forgotten.

Conclusion

The Byford Dolphin accident was a tragic event that highlighted the dangers faced by workers in the offshore oil and gas industry. It served as a catalyst for significant reforms in safety protocols and equipment standards, shaping the industry into what it is today. By understanding the causes and consequences of the accident, we can appreciate the advancements made in safety and the ongoing need for vigilance.

We encourage readers to reflect on the lessons learned from the Byford Dolphin accident and consider how they apply to other high-risk industries. Share your thoughts in the comments below, and don't forget to explore our other articles on safety and industry best practices. Together, we can continue to promote a culture of safety and prevent future tragedies.